The Evolution of In-Mold Decorations in Production Processes

The Evolution of In-Mold Decorations in Production Processes

Blog Article

Grasping In-Mold Decorations: Techniques, Patterns, and Ideal Practices for Ideal Outcomes

In the world of production, the art of in-mold decorations stands as a crucial aspect of item design and manufacturing. In-Mold Decorations. By delving right into the approaches, fads, and best techniques that underpin successful in-mold design processes, services can open a world of possibilities that not only boost the aesthetic appeal of their products however also streamline manufacturing performance and strengthen customer involvement.

Material Selection

Product choice is a crucial aspect of mastering in-mold designs, as it directly impacts the quality and resilience of the last product. When choosing materials for in-mold decors, it is necessary to take into consideration aspects such as compatibility with the molding procedure, the preferred aesthetic end result, and the ecological problems the item will deal with.

In addition, products with high heat resistance are preferred for in-mold designs, especially for items that will certainly be revealed to raised temperature levels throughout their lifecycle. By carefully picking the appropriate product for in-mold decors, manufacturers can enhance the overall quality and longevity of their products, fulfilling the assumptions of both end-users and customers - In-Mold Decorations.

Style Innovation

An important consider advancing the field of in-mold decors is the continual expedition and application of layout development techniques. Layout technology plays an important duty in improving the visual charm, capability, and total quality of products manufactured making use of in-mold decor processes. By incorporating innovative layout aspects, producers can distinguish their products in the marketplace, bring in customers, and remain in advance of rivals.

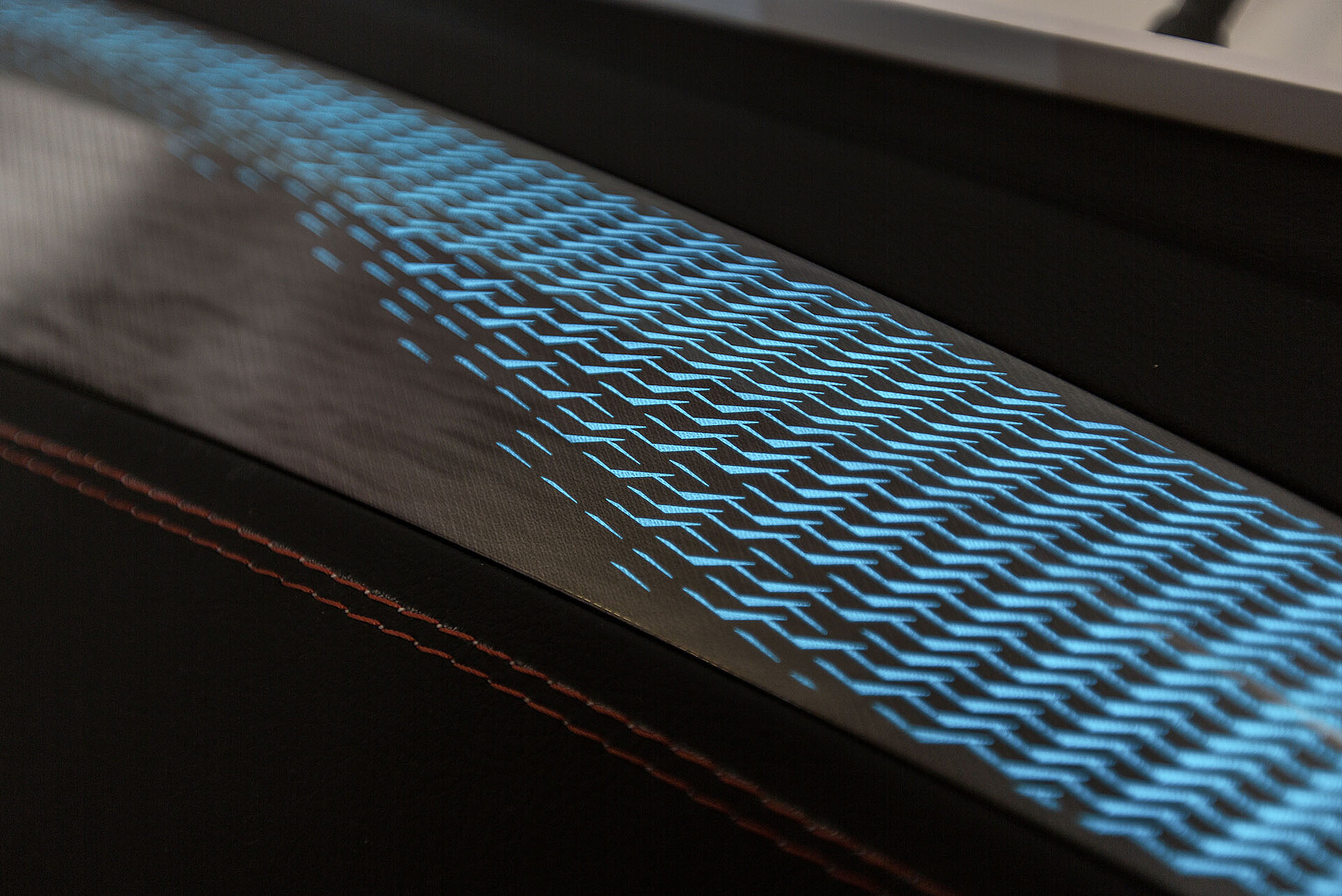

Among the crucial elements of design advancement in in-mold decorations is the assimilation of complex patterns, textures, and graphics that were formerly challenging to attain with conventional decoration techniques. Advanced technologies such as 3D printing and electronic design devices enable developers to produce complex and in-depth designs that can be flawlessly transferred onto shaped components. In addition, using dynamic shades, metallic coatings, and special effects like gloss or matte textures can even more boost the visual charm of in-mold decorated products.

Furthermore, layout technology extends beyond aesthetic appeals to incorporate functional improvements such as ergonomic forms, incorporated features, and adjustable components that deal with certain individual demands. By embracing style technology, manufacturers can unlock brand-new opportunities for product, imagination, and personalization differentiation in the competitive landscape of in-mold designs.

Manufacturing Performance

Efficient production procedures are crucial for equating the ingenious designs created in the area of in-mold designs into top quality finished items that satisfy market needs and customer expectations. In the realm of in-mold decors, production efficiency incorporates different key facets that add to the total success of the manufacturing process.

In addition, executing automation and robotics in the assembly line can dramatically boost effectiveness by streamlining recurring tasks and lowering the margin of error. Automation not just speeds up the manufacturing process but likewise boosts precision and repeatability, bring about an extra top notch and uniform final product. Embracing lean production concepts, such as just-in-time inventory administration and waste decrease strategies, can additionally boost production effectiveness by minimizing downtime and go enhancing source usage. Generally, an all natural approach to production efficiency is critical in optimizing the potential of in-mold design strategies and attaining optimal results in the open market landscape.

Quality Assurance Steps

What are the essential techniques for making certain stringent quality control steps in the realm of in-mold decorations? Quality assurance actions are extremely important in in-mold design processes to guarantee the manufacturing of high-grade and remarkable ended up items. One critical method is the application of rigorous inspection methods at every phase of the production process. This involves performing extensive visual inspections, dimensional checks, and shade consistency analyses to determine any disparities or issues early.

Making use of sophisticated modern technologies such as automatic examination systems can also improve the quality assurance procedure by providing reputable and exact data look at more info for evaluation. These systems can spot blemishes that might be missed by hand-operated inspections, therefore improving general item high quality and uniformity.

Normal training and advancement programs for workers associated with the in-mold decoration procedure can likewise add to maintaining top quality criteria. By informing staff on finest practices, quality expectations, and the relevance of attention to detail, firms can promote a culture of top quality awareness throughout the organization.

Consumer Appeal

To boost the bankability of in-mold decoration items, recognizing and catering to customer preferences play a vital duty in identifying their appeal and success. Using personalization alternatives such as tailored styles, shade variations, and textural elements can substantially enhance the allure of in-mold decoration products.

Final Thought

In-mold decorations use a flexible and efficient method to improve product looks. Understanding in-mold designs requires a holistic strategy that thinks about all elements of the manufacturing procedure to make sure success.

In the realm of production, the art of in-mold designs stands as a critical aspect of item style and manufacturing. Style technology plays a critical function in enhancing the visual charm, capability, and general quality of items manufactured utilizing in-mold design procedures.One of the crucial aspects of layout development in in-mold decors is the integration of detailed patterns, structures, and graphics that were previously challenging to attain with standard decoration techniques.Efficient production procedures are vital for converting the ingenious layouts developed in the area of in-mold decorations into high-quality ended up products that satisfy market needs and consumer expectations. Supplying customization choices such as personalized styles, shade variations, and textural aspects can dramatically enhance the charm of in-mold decor items.

Report this page